Coding in chemical manufacturing can be challenging due to harsh production environments that can be hot, dusty or wet. To achieve reliable, high quality codes, your coding equipment should be engineered to withstand these challenges as well as near-constant production and frequent changeovers. From addressing internal quality control needs to meeting your customer’s traceability requirements, Videojet can help.

- Application

- Line Integration

- Documents

- Overview

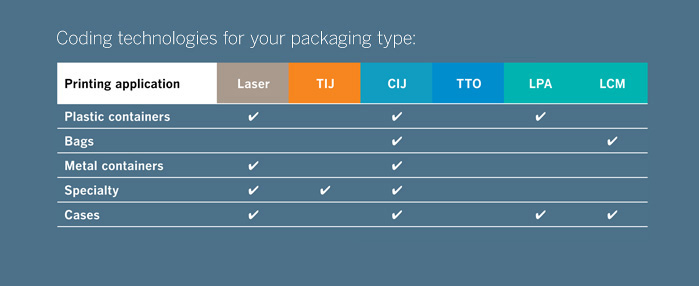

- Plastic containers

- Bags

- Metal Containers

- Specialty containers

- Cases

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

Coding done right

Coding on plastics can have its challenges, including ink adherence on slick plasticizers and code resilience in the event of chemical spillage. The optimal coding solution takes into consideration your environment, your substrate and your required ink resiliency. Coding experts at Videojet can help you through this process of selecting and integrating the right solution for your needs.

Laser Marking Systems

- Ideal for crisp, clear and permanent coding; utilizes virtually no consumables

- Comprehensive portfolio of laser accessories such as beam turning units to simplify line integration and optimize laser performance

- Capable of both direct-to-plastic and label printing

Continuous Inkjet

- Non-contact printing solution to code virtually anywhere on your package

- Specialized inks for optimized adhesion and code durability on plastic

- Code Assurance designed to minimize human error, and reduce code-related rework

Ink adhesion and coder selection

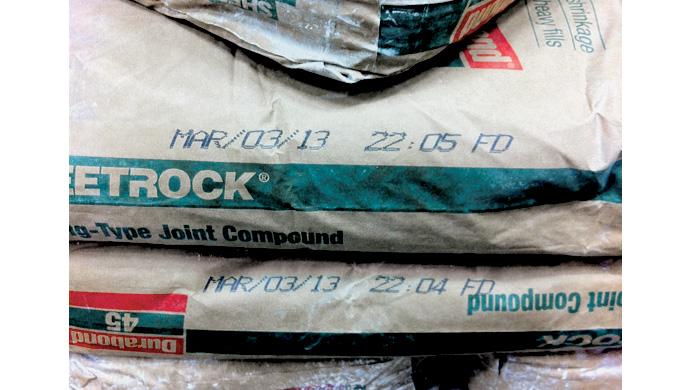

Whether your environment is hot, dusty or wet, selection of an optimal coding solution and ink is going to be key to your marking success. Videojet offers specialized solutions including printers with anti-clog printheads and specialty inks that are fast-dry, heat, and oil-resistant. With so many variables an options, it is important that you partner with a leader in the coding industry who can help you test varying solutions and identify the right coding and ink solution for your production environment.

Large Character Marking

- Produces large characters, even on uneven surfaces, to convey product information throughout supply chain

- Patented micro-purge process helps maintain a clean printhead and improves ink utilization

- Leader/follower functionality enables printing on opposing sides of sacks, providing code visibility regardless of products’ position on pallets

Continuous Inkjet

- Dynamic Calibration™ regulates ink viscosity in extreme temperatures, improving code quality; CleanFlow™ printheads resist ink build-up, lessening maintenance requirements

- Portfolio of over 175 inks including odorless and non-MEK inks

- Wide range of both dark and light colored inks for maximum contrast

Flexible solutions for a diversity of containers

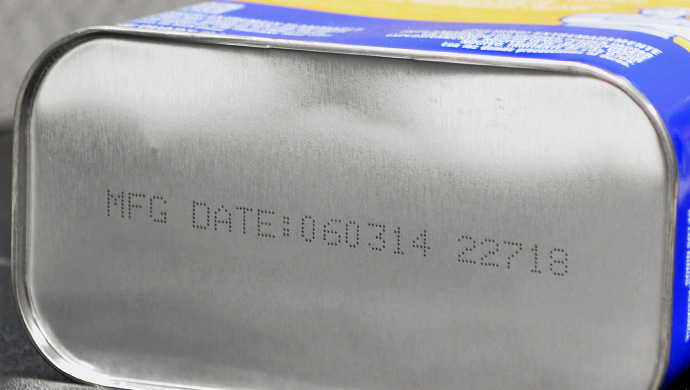

Selection of an ideal coding solution for metal containers should consider several factors, including packaging shape and size as well as desired resolution and permanence. Laser, for example, can provide a high-resolution, permanent code, but is most effective on certain shapes and substrates. Continuous ink jet offers more substrate flexibility as well as a variety of ink alternatives. This makes an experienced coding partner invaluable as you navigate the printer selection process.

Continuous Inkjet

- Easy integration into your line for shoulder, top or bottom printing on a wide variety of substrates

- Ideal solution for printing on curved metal surfaces

- Patented CleanFlow™ technology uses positive air pressure and a perforated face plate to keep the printhead cleaner longer – helping to eliminate unplanned downtime

Laser Marking Systems

- No inks or fluids are required, thereby eliminating the potential of ink compromising product integrity

- Wide range of laser sources, marking heads, and lenses to accommodate a variety of applications

- Fume extraction systems and accessories (such as an air knife) help keep the production environment and marking lens clean

Code on almost anything

Many specialty and fine chemicals come in unique containers, based on brand differentiation strategies as well as product use and dispense method. Ensure a high quality, consistent code, no matter what the container design, by choosing the optimal coding technology for your specialized package.

Continuous Inkjet

- Versatile coding solution for almost any substrate, size or color requirement

- Configurable with a 50 micron nozzle to deliver code in small areas

- Smart Cartridge™ fluid system virtually eliminates waste, mess and mistakes

Laser Marking Systems

- High-resolution scribing technology provides excellent code resolution

- Variety of marking fields for varying product sizes and line speeds

- Clear codes, logos and text etch into glass packaging helping to ensure permanence and protection

Thermal Inkjet

- High resolution, ink-based printing with no wear parts, minimizing maintenance and related downtime

- Water and light solvent inks are available for porous substrates

- 8610 uses MEK-based inks for excellent adhesion on non-porous substrates

Improve traceability and help reduce case-related costs

Printing lot, batch and supplier-specific information clearly on your cases creates a traceability point that is visible to your warehouse, wholesaler and retailer. This information provides vital product information, allows for rapid identification and helps to more quickly move product through your supply chain. To accomplish this, Videojet offers multiple GS1 approved solutions. Aside from improving traceability and assisting in product movement, printing this information directly on the case simplifies packaging demands and helps reduce case-related costs by standardizing to a common box style for different trading partners.

Label Printer Applicator

- Automatic application of high quality printed labels, designed for ease of use and low maintenance

- Direct Apply™ labeling increases performance with on-demand label application up to 150 packs per minute (typical 4” x 6” label)

Laser Marking Systems

- A DataLase® (a contrast enhancer) coated case marked with a laser will produce a dark black and extremely high resolution print

- Ablating painted or labeled surfaces provides highly-legible codes

Large Character Marking

- Eliminates cost, storage and management of labels and need for customer-specific pre-printed cases

- Solution with patented micro-purge process purges ink in programmable intervals to help keep the printhead free of debris for best print quality

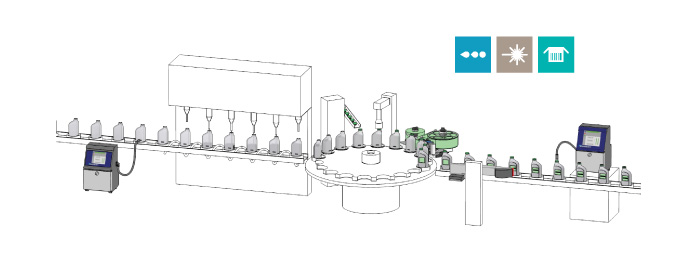

- Filling line

- Bag filler and sealer

- Specialty

- Case packer and sealer

Filling lines are typically continuous motion, with limited space for coder integration. We offer small footprint, easy to integrate solutions for both direct-to-product coding or print and apply labeling applications.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

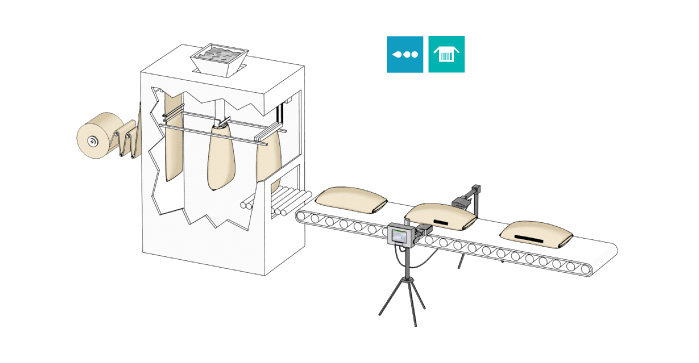

Sack filler and sealer lines can be intermittent or continuous motion. We have solutions for both. Additionally, our dual head printers allow customers to print on both sides of sacks simultaneously with a single user interface.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

For specialty containers, a side grip conveyor is often used to control products and assure proper code orientation. Videojet has experience integrating a variety of coding technologies into side grip conveyors and other material handling solutions.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Ink-based, non-contact printing using heat and surface tension to move link onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

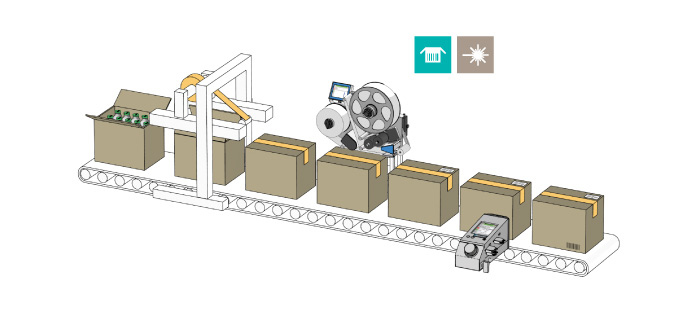

Case printers are typically integrated on conveyors after the sealed case has been discharged. Videojet offers solutions ranging from high resolution images and bar codes for product identification to batch and lot numbers for product tracking.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.