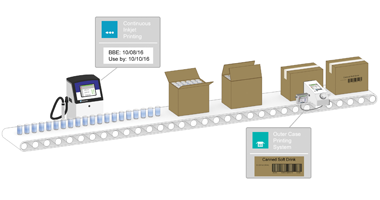

Labeling systems are used to apply preprinted labels to products, individual packages, cartons, cases, and pallet loads for product identification and traceability. They are also used to apply labels to products to promote the manufacturer’s brand image. The content of these labels can vary from a simple black & white bar code, 1D or 2D code used for identification, to a complex multicolor product label carrying eye-catching brand identity.

Automatic and semi-automatic labeling systems

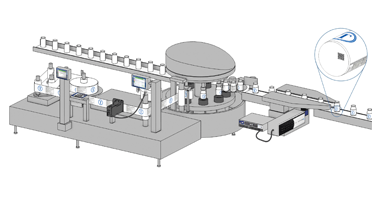

Labeling systems are available in a variety of configurations, each suited to applying labels that meet a specific need. Semi-automatic label printer applicators are set up to manually supply labels to be applied on individual products. Fully automatic labeling machines are integrated into the production process, applying labels to passing products at production line speeds.

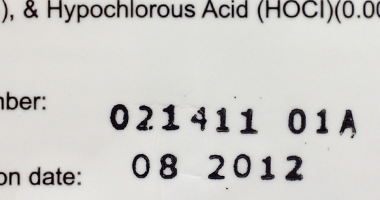

Labeling solutions include print-and-apply label printer applicators that produce labels individually that are then applied to packages or shipping loads, and case labelers that record contents of the case. In addition to identifying products, labeling solutions can place labels that record product ingredients, the temperature at which products have been stored, the brand owner’s brand image, shipping address, etc. They can also print the size type the customer requires, as well as ensuring clear, readable characters and bar codes.

On the production line, labeling solutions are integrated with other line systems and automatically receive the products or packages to be labeled.

Selecting a labeling system can be tricky, with several factors involved such as cost, speed, automation, and integration. Contact Videojet to select the right labeling system to match your business’s operational needs.

White Paper

Suggested Solutions

Videojet 9550 Print & Apply | Videojet® P3400

Related Articles